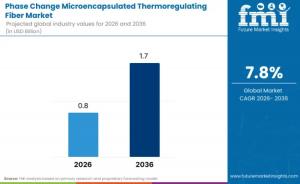

Phase Change Microencapsulated Thermoregulating Fiber Market Set to Reach USD 1.7 Billion by 2036

PCM thermoregulating fiber market grows at 7.8% CAGR as endurance, energy efficiency, and supply control reshape demand.

NEWARK, DE, UNITED STATES, February 5, 2026 /EINPresswire.com/ -- Market Overview: From Comfort Feature to Thermal Infrastructure

The global Phase Change Microencapsulated Thermoregulating Fiber Market is projected to expand from USD 0.8 billion in 2026 to USD 1.7 billion by 2036, registering a 7.8% CAGR. Market momentum is being reshaped by a fundamental shift in buyer expectations—from short-term cooling effects to long-term, durable thermoregulation embedded directly into textile systems.

Early adoption focused on apparel-driven “cool-touch” demonstrations. Current growth, however, is being driven by passive thermal buffering requirements in bedding, mobility interiors, and infrastructure-adjacent textile applications, where performance must remain consistent after laundering, compression, and extended use cycles.

Request For Sample Report | Customize Report | Purchase Full Report–

https://www.futuremarketinsights.com/reports/sample/rep-gb-31813

Buyer Value Reset: Durability Overtakes Sensory Appeal

Procurement strategies across textile and industrial segments are tightening. Buyers are increasingly defining value based on:

- Proven thermoregulation after repeated laundering

- Stability under mechanical compression and abrasion

- Batch-to-batch consistency at industrial scale

This shift explains the market’s movement away from coating-heavy PCM finishes toward fiber-integrated and melt-spun PCM architectures, which reduce wash-off risk and preserve textile hand-feel. These integrated formats lower complaint rates and improve qualification success in long-cycle product categories.

Integration Strategy Emerges as a Competitive Advantage

Microencapsulated-in-fiber systems account for a dominant share of the market, reflecting their operational reliability. Fiber-level integration allows brands and manufacturers to specify thermoregulation as a controlled yarn input rather than a variable finishing step.

This integration advantage is driving vertical control of microencapsulation capacity. Strategic moves to internalize PCM manufacturing are increasingly framed as supply-chain risk mitigation rather than expansion alone. As documented in December 2025, Alexium International’s acquisition of Microtek Laboratories strengthened U.S.-based encapsulation control, reinforcing domestic supply reliability for bedding and industrial programs.

Chemistry Landscape Broadens Beyond Paraffin

Paraffin remains the anchor chemistry, holding approximately 45% market share, due to its predictable cost-to-enthalpy performance in volume-heavy applications such as bedding. However, expansion into regulated environments—including PPE, workwear, and mobility interiors—is accelerating interest in alternative chemistries.

Key chemistry shifts include:

- Increased R&D into bio-based fatty acids

- Adoption of inorganic and silica shell systems for improved thermal stability

- Greater emphasis on leakage resistance and flame-risk perception

Rather than displacing paraffin, these chemistries are expanding the addressable market by reducing qualification friction in safety- and compliance-driven use cases.

Application Analysis: Bedding Anchors Volume, Mobility Drives Growth

Bedding and sleep products remain the largest application segment, accounting for approximately 35% of total demand. Their leadership is supported by:

- Long contact duration that makes thermal benefits perceptible

- High willingness to pay for comfort-led performance

- Lower return risk compared to powered cooling solutions

Meanwhile, mobility interiors and battery-adjacent textiles are emerging as high-growth segments. In electric vehicles, passive thermal buffering reduces HVAC energy draw, improving range efficiency and supporting tightening regulatory standards.

Regional Outlook: Policy and Platform Economics Shape Adoption

- China leads global share and is projected to grow at a 9.9% CAGR, driven by bedding scale and NEV efficiency requirements that elevate the value of passive thermoregulation.

- United States growth (9.4% CAGR) is anchored in bedding conversion and supply-chain localization, where vertical integration reduces variability risk.

- Japan advances at a 7.2% CAGR, supported by OEM-grade execution and integration of PCM with recycled fiber platforms for EV interiors.

- United Kingdom expands at 8.4% CAGR, benefiting from fiscal incentives and industrial energy-efficiency frameworks tied to battery manufacturing.

Competitive Landscape: Reliability Over Brand Narratives

Competition is separating into three execution lanes:

- Vertically integrated PCM platform owners, prioritizing supply assurance and documentation depth

- OEM-aligned innovators, combining sustainability credentials with scalable integration

- Legacy ingredient brands, facing pressure as procurement shifts toward endurance proof

Rising qualification costs and volume commitments are accelerating consolidation, favoring suppliers that deliver repeatable performance rather than marketing-led differentiation.

Market Outlook and Strategic Implications

The Phase Change Microencapsulated Thermoregulating Fiber Market is expanding because use cases have inverted. What began as a comfort-driven apparel innovation is now scaling as passive thermal infrastructure across bedding, mobility, and energy-sensitive textile systems. As decarbonization policies tighten and ROI expectations rise, PCM fibers are increasingly specified to reduce active energy loads without adding power complexity.

Get data that aligns with your strategic priorities — ask for report customization today:

https://www.futuremarketinsights.com/customization-available/rep-gb-31813

Related Reports

Bonded Magnet Market- https://www.futuremarketinsights.com/reports/bonded-magnets-market

Fireproof Aerospace Fastener Coatings Market- https://www.futuremarketinsights.com/reports/fireproof-aerospace-fastener-coatings-market

Constrained-layer Damping Tiles Market- https://www.futuremarketinsights.com/reports/constrained-layer-damping-tiles-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.